‘ICE’ a pressurised cooling research tool

Swansea University has a strong commitment to innovative research and has developed a novel, patent protected, technique for handling the freezing of pressurised liquids. As part of this project E2L were commissioned to improve an existing research tool by applying sound engineering practice to the thermal efficiency requirements of the unit, and make the system ready for presentation to major investors. Conceptually the unit was sound but required design experience input and a more direct level of practical input.

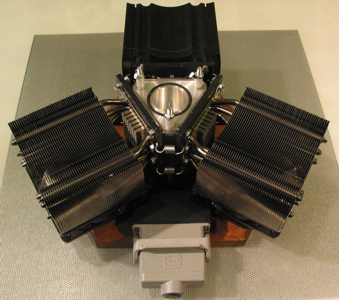

The device essentially consists of a central cooling chamber coupled to three Peltier semiconductor heaters/coolers. These heating elements are coupled to large heatsinks, each of which has air forced through it by means of a fan mounted on its underside. The cooling chamber has a thermistor for temperature measurement attached to it. The unit is bespoke and is an essential component of this major research project.

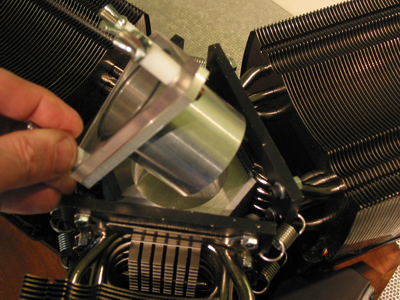

Improvements were made by E2L to the mechanical interfacing between the Peltier units and the heatsinks by producing a system whereby the presentation of the contact surfaces floated sufficiently to ensure orthogonal mating. Carefully selected springs have been added to ensure adequate pressure for good thermal contact is applied, but not to compromise the integrity of the ceramic substrates of the heaters.To improve the temperature measurement of the unit the thermistor has been buried in the material of the cooling chamber at the highest centre of mass.

The cooling fans of the unit have all been applied using rubber mounts to reduce vibration in the liquid of the cooling chamber itself and to reduce noise. To improve the general presentation of the device, the existing screw terminal interface for the wiring has been replaced with a professional high-current connector.

The project serves as a good example of a non-specified task, trusting E2L to improve a valuable tool by applying their many years experience of such systems. The project was completed within two weeks and is now being used to demonstrate a major energy saving invention for a consumer food product.